Products

Renegade Materials specializes in the aerospace market. We offer a diverse product line tailored to the challenging requirements of our customers’ applications. Our products offer solutions for fuel efficiency, weight reduction, enhanced durability, stiffness, and exceptional thermal performance in extreme conditions. Renegade Materials also offers competitive alternatives to legacy materials.

A broad portfolio of chemistries

Product offerings in a range of formats

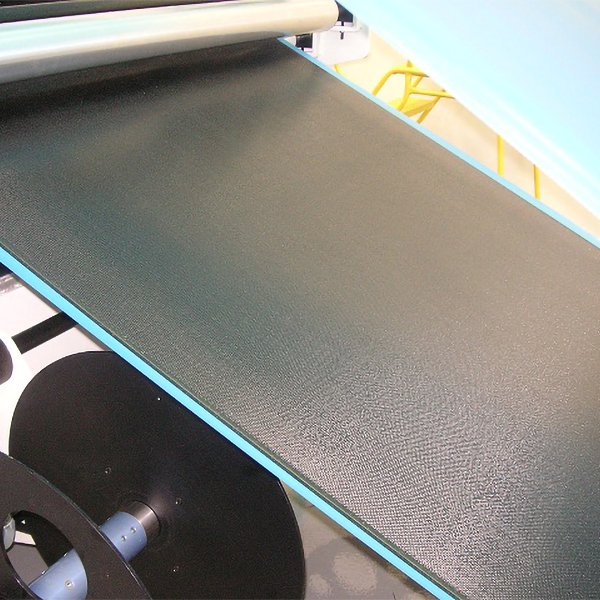

- Fabric and Unidirectional Prepregs

- Prepreg Widths up to 60-inch

- Prepreg Reinforcement Types Include: Carbon, Glass, Quartz and Ceramic Fibers

- Adhesive Films, Peel Plies, Pastes, Primers, and Syntactics

- Infusion Resins for RTM and VaRTM Processes

Products backed by:

- State-of-the-Art Production Equipment Located in Two Modern Facilities

- LEAN Manufacturing Processes

- A Focus on Continuous Improvement

- High-Rate Production Capacity

- Exceptional Process Control and Lot to Lot Consistency

- Responsive Customer Service

- Competitive Lead-Times

- Quality Management Systems assuring compliance to AS9100D and ISO 9001.

- Nadcap Accredited Non-Metallic Materials Manufacturing and Non-Metallic Materials Testing.

Product selection guide

This Selection Guide will aid you in selecting the optimum resin type for your application.

| Resin Type | Temperature Capability |

|---|---|

| Polyimide | -65°F to 750°F |

| Polyceramic Hybrid | -65°F to 2000°F |

| Bismaleimide (BMI) | -65°F to 450°F |

| Cyanate Ester | -65°F to 350°F |

| Epoxy | -65°F to 300°F |