Aerospace Infusion Resins

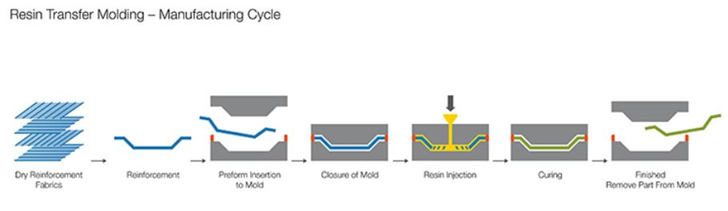

Renegade Materials is an Aerospace Industry front runner in High Temperature Materials. We understand that prepregs can offer a great solution for many structural applications. Complex part geometries and dimensional requirements, however, may make infusion processing a better approach.

Renegade Materials offers RM-3000, a one-part BMI resin for Resin Transfer Molding (RTM) as well as RM-3010, a Vacuum Assisted Resin Transfer Molding (VARTM) resin. Polyimide infusion resins are also available.

Contact us to learn more about these innovative products.

BMI Infusion Resins

Renegade Materials’ BMI Resin product line includes a Resin Transfer Moldable (RTM) resin, RM-3000 and a Vacuum Assisted Resin Transfer Moldable (VARTM) resin, RM-3010. Both are one-part systems and offer excellent processing windows.

| Product | Description | Features |

|---|---|---|

| RM-3000 | BMI RTM Resin (One Part) | Comparable to Industry Standard BMI’s; BMI Infusion Resin for Resin Transfer Molding; Excellent Hot/Wet Performance, Qualified at Major Jet Engine OEM |

| RM-3010 | BMI VaRTM Resin (One Part) | BMI Infusion Resin for Vacuum Assisted Resin Transfer Molding; <1000 cps @ 8 hours at 230°F (110°C); Excellent Hot/Wet Performance |

Features:

- Next-Generation BMI Formulation Technology

- Cost Competitive Equivalent to Industry-Standard Products

- Improved Durability and Compression-After-Impact

- Superior Hot-Wet Performance

- 350°F or 375°F Cure with Post Cure

- Continuous Service Temperatures up to 400°F

- Excellent Flame, Smoke and Toxicity Performance

Polyimide Infusion Resins

Renegade Materials leads the way in the manufacture and supply of Polyimide Materials for High Temperature Aerospace Applications.

| Product | Description | Features |

|---|---|---|

| RTM-1010 | Polyimide RTM Resin | 500-800 cps at 500°F; 2 hrs at <2000 cps, Dry Tg -580°F; also available in forms to support resin film infusion |

| RTM-1100 | Polyimide RTM Resin | 700°F Service Infusible Resin; Supplied in Powder Form |

Features:

- Polyimide Infusion Resins designed to meet challenging Aerospace Requirements

- Light Weight, Low-Cost Alternatives to Titanium and Insulation

- Non-MDA Chemistries and Modern Manufacturing Processes

- Resins are Supplied in Powder Form and Melted into Liquid Form for Infusion Processes

- Continuous Service Temperature up to 700°F

- Excellent Hot-Wet Properties and Thermal Oxidative Stability

- Low Micro-Cracking